|

|

Nanoimprint

lithography (NIL) is a new way of

nanopatterning and a revolutionary

solution to

nanomanufacturing. NIL patterns nanostructures

by the physical deformation of a deformable material

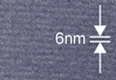

using a mold. NIL can have sub-5 nm resolution and 1% CD control,

and simultaneously achieve high-throughput, sub-10 nm structures

and low cost -- a feat currently impossible using other existing

lithographic methods. Prof. Chou's group began pioneering

developments as early as 1995 and has made a numerous breakthroughs

including the demonstration of sub-10 nm resolution.

Nanonex provides the complete nanonimprint lithography (NIL)

technology solutions: tools, resists, masks, and processes . Nanonex

technology is built on the pioneering, eight years worth

of multi-million-dollars research by Professor Chou's university research group,

which has been

greatly enhanced by Nanonex's own developments, and is

being used in research and manufacturing by industry and

academia.

Nanonex products have many

unique advantages over anything on the market. For example,

Nanonex NIL machines are based on a patented technology, that does

not use solid plate(s) to press the wafer and masks.

This new technology gives not only excellent uniformity over entire

wafer in nanoscale, but also the precise alignment and extremely

fast processing time (less than 40 sec for a

thermal plastics resists). The new technology also allows a single

NIL machine to perform all forms of nanoimprinting, including thermal and

photocurable NIL and direct nanoimprinting. NIL resists require

very little pressure to press, are fast in response, and

have high pattern fidelity and excellent uniformity.

Furthermore,

Nanonex has a strong IP portfolio to support its products

and protect its customers.

Nanonex Publications:

Hua Tan, Linshu Kong, Mingtao Li, Colby Steer and Larry Koecher, "Current Status of Nanonex Nanoimprint Solutions," SPIE, (2004).[PDF]

Mingtao Li, Hua Tan, Linshu Kong, and Larry Koecher,"Four-inch Photo-Curable Nanoimprint Lithography Using NX-2000 Nanoimprint," SPIE, (2004). [PDF]

Nanonex Customers' Publications (NX Tools/Resists Used):

Columbia University (NXB-200 & NXT-100)

[1]. Schvartzman, M. (Department of Chemical Engineering, Columbia University); Mathur, A.; Hone, J.; Jahnes, C.; Wind, S.J. “ Plasma fluorination of carbon-based materials for imprint and molding lithographic applications” Appl. Phys. Lett., (2008).[PDF]

University of California Santa Barbara (NX 2000)

[2]. Namdas, Ebinazar B. Tong, Minghong; Ledochowitsch, Peter; Mednick, Sarah R.; Yuen, Jonathan D.; Moses, Daniel; Heeger, Alan J. “Low thresholds in polymer lasers on conductive substrates by distributed feedback nanoimprinting: Progress toward electrically pumped plastic lasers” Advanced Materials, (2009). [PDF]

University of Michigan, Ann Arbor (NX 2000)

[1]. A. Maxwell, S.-W. Huang, T. Ling, J.-S. Kim, S. Ashkenazi, and L. J. Guo, “Polymer Microring Resonators for High-Frequency Ultrasound Detection and Imaging” IEEE Special Topics in Quantum Electronics (on biophtonics), (2008). [PDF]

[2]. M. G. Kang and L. J. Guo, “Semitransparent Cu electrode on a flexible substrate and its application in organic light emitting diodes” J. Vac. Sci. & Technol. B. (2007). [PDF]

[3]. M. G. Kang, and L. J. Guo, “Nanoimprinted Semitransparent Metal Electrode and their Application in Organic Light-Emitting Diodes” Adv. Mater. (2007). [PDF]

[4]. W. Hua, E. K. F. Yim, R. M. Reano, K. W. Leong, S. W. Pang, “Effects of nanoimprinted patterns in tissue-culture polystyrene on cell behavior” J. Vac. Sci. Technol. B (2005). [PDF]

Princeton University (NX 2000)

[1]. C. Wang, Q. Zhang, Y. Song, and S. Y. Chou, "Plasmonic Bar-Coupled Dots-on-Pillar Cavity Antenna with Dual Resonances for Infrared Absorption and Sensing: Performance and Nanoimprint Fabrication," ACS Nano 8 (3) 2618-2624 (2014). [PDF]

[2]. W. D. Li, X. Liang, and S. Y. Chou, “Nanoscale negative-tone quantized patterning by novel selective electrochemical etching of a nanoimprinted sub-200 nm bimetallic tile array,” Nanotechnology 23 (35) 355303 (2012). [PDF]

[3]. Xiaogan Liang, Keith J. Morton, Robert H. Austin, and Stephen Y. Chou, “Single Sub-20 nm Wide, Centimeter-Long Nanofluidic Channel Fabricated by Novel Nanoimprint Mold Fabrication and Direct Imprinting” Nano Lett., (2007). [PDF]

[4]. Walter Reisner, Keith J. Morton, Robert Riehn, Yan Mei Wang, Zhaoning Yu, Michael Rosen, James C. Sturm, Stephen Y. Chou, Erwin Frey, and Robert H. Austin, “Statics and Dynamics of Single DNA Molecules Confined in Nanochannels”,Phys. Rev. Lett. (2005). [PDF]

[5]. Lotien Richard Huang, Edward C. Cox,Robert H. Austin, James C. Sturm, “Continuous Particle Separation Through Deterministic Lateral Displacement”,Science (2004).[PDF]

[6]. Wei Zhang, Stephen Y. Chou, “Fabrication of 60-nm transistors on 4-in. wafer using nanoimprint at all lithography levels” Appl. Phys. Lett., ( 2003).[PDF]

[7]. Mingtao Li, Lei Chen, Wei Zhang and Stephen Y Chou, “Pattern transfer fidelity of nanoimprint lithography on six-inch wafers”,Nanotechnology (2003). [PDF]

National Tsing Hua University, Taiwan, Republic of China (NX 1000)

[1]. Sun Zen Chen, Jen Fu Liu, Henry J. H. Chen, Fon Shan Huang, “Study of nanoimprint pattern transfer on hydrogen silsesquioxane”, J. Vac. Sci. Technol. B ( 2006). [PDF]

National Institute of Standards and Technology (NX 2000)

[1]. Ro, Hyun Wook ; Ding, Yifu; Lee, Hae-Jeong; Hines, Daniel R.; Jones, Ronald L.; Lin, Eric K.; Karim, Alamgir; Wu, Wen-Li; Soles, Christopher L. “Evidence for internal stresses induced by nanoimprint lithography” J. Vac. Sci. Technol. B ( 2006).[PDF]

[2]. Lee, Hae-Jeong; Ro, Hyun Wook; Soles, Christopher L.; Jones, Ronald L.; Lin, Eric K.; Wu, Wen-Li; Hines, D.R. ”Effect of initial resist thickness on residual layer thickness of nanoimprinted structures” J. Vac. Sci. Technol. B, (2005).[PDF]

Institute of Bio- & Nanosystems (IBN), Germany (NX 2000)

[1]

Gilles,S.; Meier,M.; Prömpers,M.; van der Hart,A.; Kügeler,C.; Offenhäusser,A.; Mayer,D."

UV nanoimprint lithography with rigid polymer molds" Microelectronic Engineering, (2009) [PDF]

|